Back

Auto Drain Valve Blue Ball Timer Drain Valve for Air Compressor Spare Parts for Refrigerated Air Dryer

Features

Blue Ball Timer Drain Valve

Auto drain valve is made of solid state electronic time setting and solenoid valve, which can make the compressor condensates water drain automatically. It is widely used in filter drier, oil/water segregator, refrigerant compressed air drying machine, drying machine, air compressor dripfeet, and so on. The time of drain and interval can be adjusted according to different needs.

Business range:

Screw air compressor

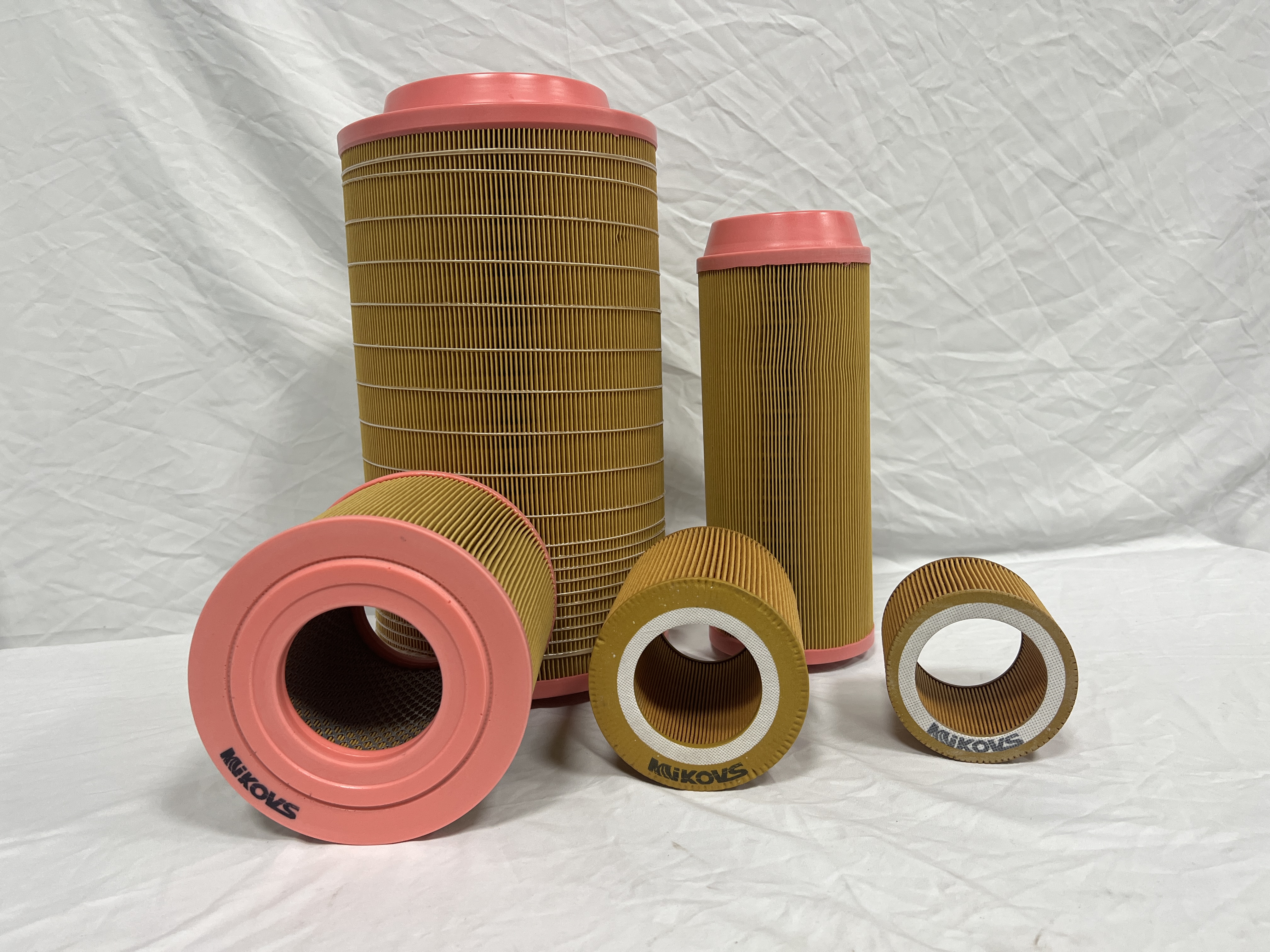

Screw air comrpessor spare parts

Airend, Used air compressor, Oil free spare parts Shaft Seal/ Sleeve Temperature Sensor / Pressure Sensor Solenoid Valve/ Thermostat Valve/ Air intake Valve / Minimum Pressure Valve/ Blow Off Valve Wheel Gear / Oil Level Indicator/ Master Controller Preventive Maintenance Kits / Air Filter / Oil Filter / Oil separator / Filter element / Compressor Oil and so on.

No matter what you want, just send me your part no. , favorable price will be quoted Immediately.

RFQ

Q1. Are you trading company or manufacture ?

A: We are professional manufacture of screw air compressor more than 8 years.

Q2. How long is the delivery time ?

A: For standard voltage ,15 working days. Non-standard ,please contact our sales.

Q3. What’s payment term ?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, and etc. Also we could accept USD, RMB, Euro and other currency.

Q4. How about your after-sales service ?

A: 1.Provide customers with installation and commissioning online instructions.

2. Well-trained engineers available to overseas service.

3.Worldwid agents and after service avaiable.arrange our engineers to help you training and installation.

Q5. How about your warranty?

A: One year for the whole machine and two years for screw air end, except consumable spare parts.

Q6. Do you have any certificate ?

A: Yes, per different customer’s market need ,we can offer CE ,ISO etc certificate.

Q7. What about the maintenance ?

A: First maintenance need to be done after 500Hours, and then every 2000-3000 hours to do the normal maintenance,

and consider the actual environment.

Q8. How do you control quality ?

A: 1.Raw- material in checking.

2.Assembly.

3.Worldwid after service available.arrange our engineers to help you training and installation.

Q9. Do you offer OEM service ?

A: Yes.

Our expertise is here to serve you

Send us your request for quotation and we will generate a quote with everything you need for your glass bottle project.

-

On-trend design

-

Decoration & Labeling

-

Accessory supply

-

Warehousing & logistics

Submit Your Request

Consult your compressor solution

With our professional products, energy-efficient and reliable compressed air solutions, perfect distribution network and long- term value-added service, we have win the trust and satisfactions from the customer all over the world.

Our Case Studies